Imec has developed a new technique to make tiny little lasers directly on standard silicon wafers, enabling cheaper and better optical technology.

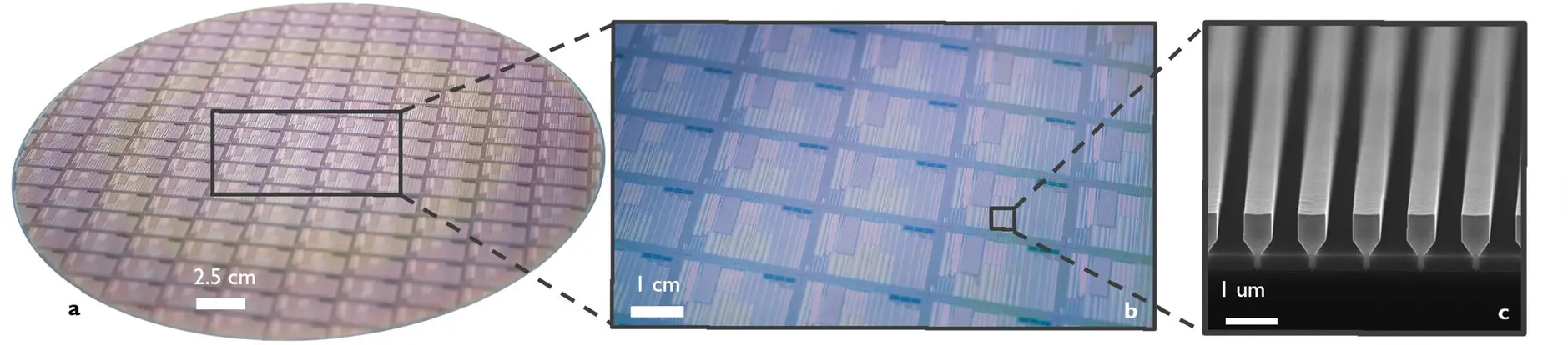

Imec has succeeded in fabricating complete wafers of electrically driven GaAs nanoride gel lasers on 300 mm silicon wafers. In human terms: Imec has built tiny lasers on a wafer via a scalable technology that can simplify the integration of classical chips and optical technology. This breakthrough opens the way to cost-efficient and high-performance optical devices for applications such as data communications and AI.

Breakthrough in silicon photonics

Researchers have produced electrically pumped nanoride gel lasers with multi-quantum-well structures completely monolithically on standard silicon wafers. The lasers achieve continuous operation at room temperature with threshold currents as low as 5 mA and optical power in excess of 1 mW. This marks an important step in the development of optical sources integrated into CMOS processes.

The growth process used by Imec avoids the complexity and high cost of hybrid integration techniques such as flip-chip or wafer bonding. Traditional methods often require expensive III-V substrates, which is inefficient and less sustainable. In contrast, Imec’s approach with direct growth on large silicon wafers is a scalable and sustainable solution.

Fewer defects

The integration of III-V materials on silicon is complicated by differences in crystal structure and thermal expansion. This mismatch causes defects that reduce the performance and reliability of lasers. Imec uses selective growth techniques such as aspect-ratio trapping (ART) and nano-ridge engineering to address these problems. These methods minimize defects.

Imec’s GaAs nanoride lasers incorporate InGaAs multi-quantum-well structures for optical amplification. These are integrated into a p-i-n diode and coated with a protective InGaP layer. The lasers operate at a wavelength of 1020 nm and achieve efficiencies of up to 0.5 W/A with a maximum optical power of 1.75 mW.

This development, according to imec, is an important milestone for the further advancement of silicon photonics and paves the way for large-scale integration of optical technology into CMOS manufacturing processes.