Bekaert, an international company with two headquarters in Belgium, has been investing in artificial intelligence in recent years.

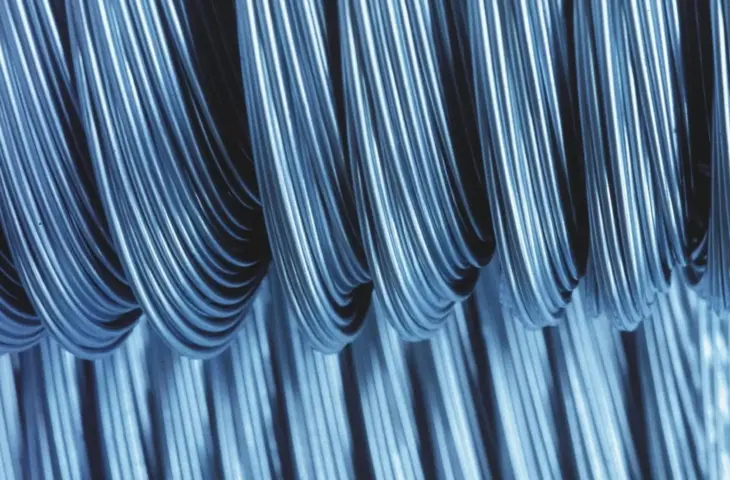

In a conversation with Koen Vereeken, Global IT Lead Technology Infrastructure at steel wire company Bekaert, we learn more about how the company optimizes its processes with artificial intelligence. By training their own AI models with thousands of photos, the inspection of steel wire is much faster.

Smart Inspection Equipment with AI

“We have developed a device that inspects ropes using AI,” says Vereeken. The device uses 360-degree cameras that capture detailed images of the cables. These images are then analyzed to detect wear, corrosion, and other damage. “Where human inspectors used to spend hours, AI now takes over much of the work.”

The modernization focuses on increasing speed and making the process completely wireless. “Thanks to wireless communication, we can upload data to the cloud faster, which saves a tremendous amount of time,” he adds.

From Prototype to Product

The project began in 2023, and the first prototype was ready by the end of that year. “We are now in the phase where we are moving from prototype to a customer-friendly product,” says Vereeken. Although there are still challenges, such as improving the accuracy of AI models, the development is proceeding as planned.

A significant obstacle was collecting quality data to train the AI models. “We need thousands of photos of different damage categories. Historical data helps, but many photos are not usable due to inconsistencies in resolution and lighting,” Vereeken explains.

Efficiency through Fast Rendering Time

HP plays a crucial role in the development of synthetic data that Bekaert uses to train its AI models. “We use HP ZBooks for generating this data. These are powerful workstations that can render complex 3D models,” Vereeken said.

AI Lowers the Threshold for Considering New Applications

Koen Vereeken

This synthetic data not only helps to train the AI faster but also ensures that the system remains reliable with different types of damage and conditions. “Without this hardware, we would never achieve the same efficiency,” he emphasized.

Collaboration and Innovation

Bekaert collaborates with academic institutions to improve data collection and standardization. “We have consulted various individuals and universities to improve our Vision AI models,” says Vereeken. This collaboration has not only advanced the technology but also opened up new possibilities for other applications.

The merger of teams within the company has also helped. “This was the first time we brought people from different disciplines, such as hardware engineering and cloud experts, together in one project team. This required a new approach but led to strong synergies,” according to Vereeken.

With the development of this inspection system, Bekaert is taking a step towards an innovative future. “AI lowers the threshold for considering new applications,” Vereeken knows. Bekaert sees opportunities to further expand this technology to other products and processes.